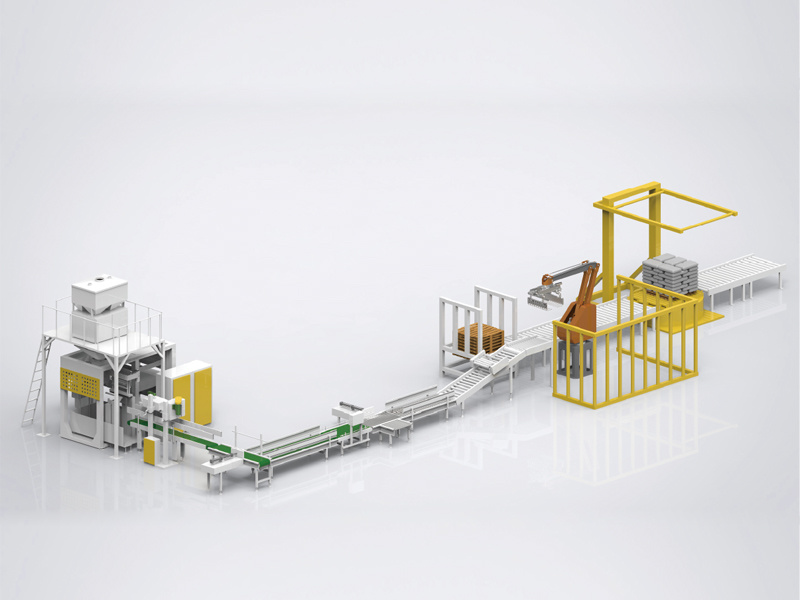

Professionally provide a full range of weighing and packaging production line solutions

Professionally provide a full range of weighing and packaging production line solutions

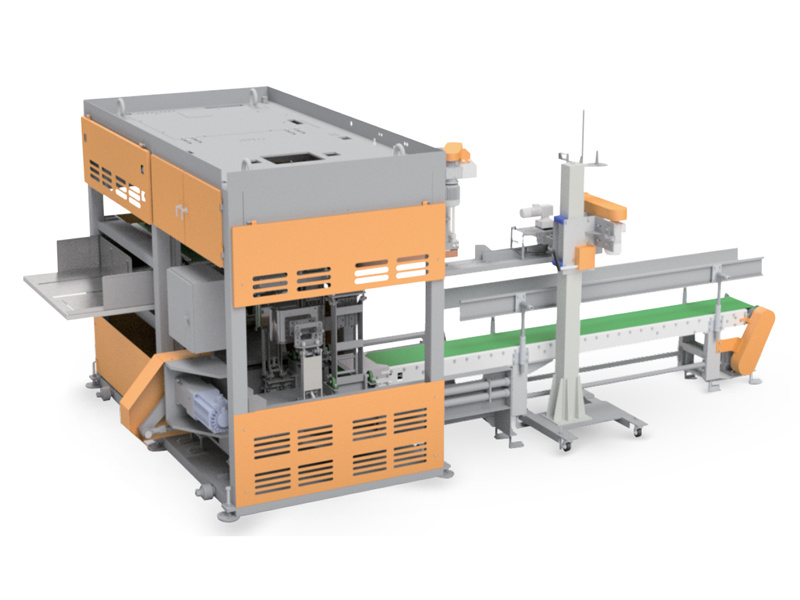

Roll film type small packaging automatic solution

Key words: Packing speed

Description

Four-head high-speed computerized quantitative packaging scale (standard type, cold-resistant type)

Metering parameters:

Model: DCS1-4, DCS2.5Q-4, DCS5Q-4

Weighing range: 0.4~1kg, 0.5~2.5kg, 2~5kg (recommended)

Packing speed: 1200-2400 bags/hour

Accuracy: X(0.2) level

Power supply: AC220V/380V, 50Hz

Air pressure: 0.5~0.8Mpa

Air consumption: 2 cubic meters per minute

Applicable materials: Seeds, feed, melon seeds, rice, plastic granules, grains, miscellaneous grains, white sugar, puffed food, washing powder and other granular materials with good fluidity or sheet materials with average fluidity.

Structural features: the combination of adjustable pneumatic valve and vibrating feeding method, four-scale structure, precise and high-speed

Basic configuration: weighing controller: all imported hardware, American A/D converter, Japanese Panasonic optocoupler relay; software part of computer software control technology, independent research and development, with all independent intellectual property rights;

Load cell: low temperature compensation to -30℃, customized production in the United States, supervised by Knight

Cylinder solenoid valve: AirTAC Taiwan, WPI

Advantages of quantitative packaging scales:

1. High precision: better than similar products.

2. Fast speed: our high-speed four-scale scale is equivalent to the speed of other peers' six-scale scales.

3. Independence: It has four independent weighing systems and four anti-interference technologies. In the weighing process, if there is a problem with one of the weighing units, other scales can work normally, while the same manufacturers basically share one control panel for multiple scales. If there is a problem with one of the weighing units, other scales will be affected at the same time. , the entire system collapsed, causing the entire production line to stop.

4. Low temperature resistant load cell: The company develops special customized low temperature compensation to -30℃ (national standard -10℃) to ensure excellent linear output in cold areas.

Industry experience:

1. 21 years of professional experience in weighing and packaging

2. "GB/T 27738-2011 Gravity Type Automatic Loading Weighing Apparatus" (Quantitative Packaging Scale) National Standard Participating Organization

3. The company is Jiangsu Province Intelligent Weighing System Engineering Technology Research Center

4. Editor-in-chief of "Gravity Automatic Loading Weighing Apparatus" (Quantitative Packaging Scale) National Vocational Education Training Elementary, Intermediate and Advanced Textbooks

Film wrapping machine (standard type, cold-resistant type)

Model: NTBM-500, 620, 800

Material of the main body: optional stainless steel or full stainless steel in contact with the material

Packing capacity: 20-60 bags/min

Bag size: bag length: 100-300(350)mm, 100-380mm, 100-480mm

Bag width: 80-240mm, 110-300mm, 160-385mm

Packaging machine accessories: sponge exhaust device——squeeze bag air

Bag support device——a device installed under the horizontal seal to support overweight materials

Anti-clamping device——material buffering, the surface of the anti-clamping rod is added with silica gel, which plays a buffering role

Safety device——Once the door of the packaging machine is opened during operation, the operation will stop immediately

Main configuration: imported Mitsubishi PLC control, Taiwan Weilun touch screen operation, Japanese Panasonic servo system, German Shike photoelectric, imported electrical components, Japanese SMC solenoid valve and cylinder, reducer plus antifreeze lubricant, special air control box Cold-resistant heating device.

Packaging machine product advantages:

1. Once the film wrapping machine is abnormal during the working process, the equipment will alarm and stop automatically (such as material clamping, no ribbon, broken bag, etc.), which can reduce the waste of coil materials.

2. The film pulling of the film wrapping machine uses one motor with two reducers, which can improve the synchronization of film pulling and reduce the phenomenon of deviation.

3. A bag support mechanism is added under the film rolling machine packaging machine, which can reduce broken bags.

4. The roll film packaging machine adopts the form of three-sided back-sealing bag making, high-precision intelligent temperature controller; the horizontal sealing adopts a cooling device.

5. The control power supply of our scale and film winding machine is isolated from each other to reduce mutual interference of equipment. The two signals are handshake signals, which enhance the reliability of the device.

6. The controllers of our packaging scales are independent of each other. Once there is a problem with one of them, the entire production line will not be able to work.

Related Products

naite8880@163.com

naite8880@163.com WhatsApp

WhatsApp 0510-85342300

0510-85342300