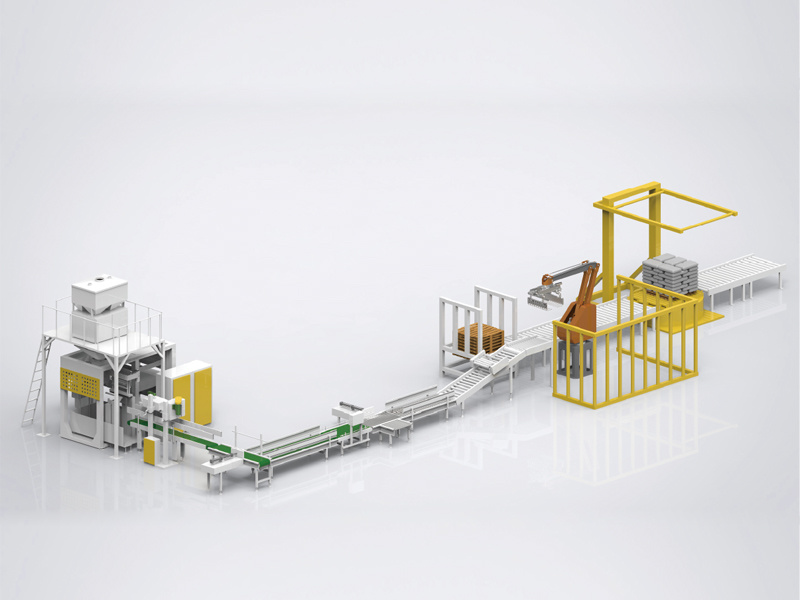

Professionally provide a full range of weighing and packaging production line solutions

Professionally provide a full range of weighing and packaging production line solutions

DCS2.5Q-4, 5Q-4 roll film automatic packaging machine

Key words: Packing speed

Description

Packing speed: 1200~2400 packs/hour

Weighing range: 0.5~2.5kg (2~5kg)

Accuracy class: X(0.2) class

Host power: 3800W

Air pressure: 0.6MPa

Applicable materials: Seeds, feed, melon seeds, rice, plastic granules, grains, miscellaneous grains, white sugar, puffed food, washing powder and other granular materials with good fluidity or sheet materials with average fluidity.

Mechanism features: ①Adjustable pneumatic valve + vibration feeding ②Four-scale high-speed structure ③It can be matched with automatic bagging machine or automatic film rolling machine.

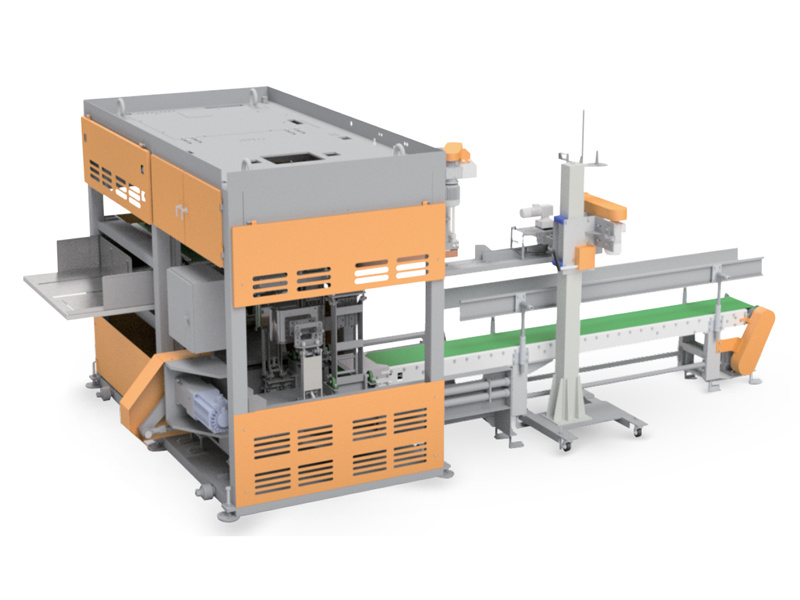

Film wrapping machine (standard type, cold-resistant type)

Model: NTBM-500, 620, 800

Material of the main body: optional stainless steel or full stainless steel in contact with the material

Packing capacity: 20-60 packs/min

Bag size: bag length: 100-300(350)mm, 100-380mm, 100-480mm, can be customized

Bag width: 80-240mm, 110-300mm, 160-385mm

Packaging machine accessories: sponge exhaust device——squeeze bag air

Bag support device——a device installed under the horizontal seal to support overweight materials

Anti-clamping device——material buffering, the surface of the anti-clamping rod is added with silica gel, which plays a buffering role

Safety device——Once the door of the packaging machine is opened during operation, the operation will stop immediately

Main configuration: imported Mitsubishi PLC control, Taiwan Weilun touch screen operation, Japanese Panasonic servo system, German Shike photoelectric, imported electrical components, Japanese SMC solenoid valve and cylinder, reducer plus antifreeze lubricant, special air control box Cold-resistant heating device.

Product advantages of packaging machine:

1. Once the film wrapping machine is abnormal during the working process, the equipment will alarm and stop automatically (such as material clamping, no ribbon, broken bag, etc.), which can reduce the waste of coil materials.

2. The film pulling of the film wrapping machine uses one motor with two reducers, which can improve the synchronization of film pulling and reduce the phenomenon of deviation.

3. A bag support mechanism is added under the film rolling machine packaging machine, which can reduce broken bags.

4. The roll film packaging machine adopts the form of three-sided back-sealing bag making, high-precision intelligent temperature controller; the horizontal sealing adopts a cooling device.

5. The control power supply of our scale and film winding machine is isolated from each other to reduce mutual interference of equipment. The two signals are handshake signals, which enhance the reliability of the device.

6. The controllers of our packaging scales are independent of each other. Once there is a problem with one of them, the entire production line will not be able to work.

Related Products

naite8880@163.com

naite8880@163.com WhatsApp

WhatsApp 0510-85342300

0510-85342300